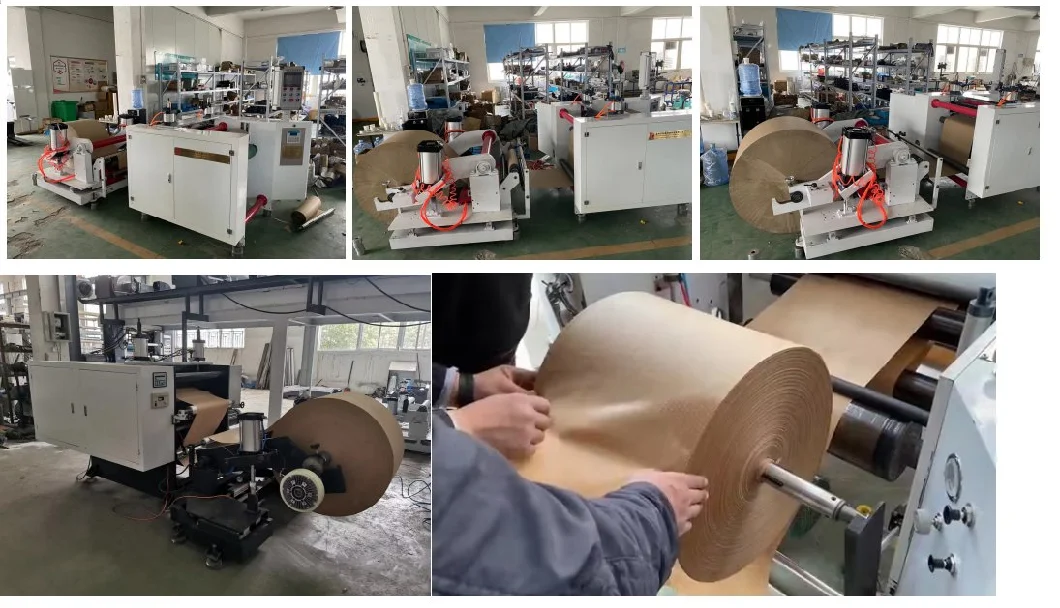

Cushioning Wrap Honeycomb Paper Making Machine

Basic Info.

| Model NO. | / |

| Certification | ISO 9001:2000, CE |

| Automation | Automatic |

| Suitable for | Recycled Material, Paper |

| Paper Thickness | Thin Paper |

| Cutting Speed | 100-120m/Minute |

| Machine Size | 2900X1900X1500mm |

| Key Words | Bubble Wrap Cutter |

| Winding Mandrel | 1"/1.5"/2" Options |

| Transport Package | Wooden Case |

| Specification | ): 2900(L ) x 1500(W ) x 1400 mm(H) |

| Trademark | ZHECHUANG |

| Origin | China |

| HS Code | 8477800000 |

| Production Capacity | 100 Sets/Year |

Packaging & Delivery

Package Size 290.00cm * 190.00cm * 150.00cm Package Gross Weight 1100.000kgProduct Description

500mm width protective cushion honeycomb paper making machine wrapping rolls cutter for packagingProduct Description

Characteristics

- Net making and rewinding could be completed at the same time.

- Machine is light in weight, small size, low noise.

- High efficiency and energy saving. - Fast dynamic response and stable running speed are the significant advantages.

- Adopts frequency conversion speed regulation, fully integrated circuit control. - Winding and unwinding tension is automatically controlled. - Two sections of electronic meter to ensure the accuracy.

- Batch pause and delay time can be set.

Product Parameters

Product Paramenters| SPECIFICATIONS FOR HIGH SPEED HONEYCOMB PAPER MAKING MACHINE | |

| Model | FMYY-500 |

| Unwinding width | 500mm |

| Unwinding roll diameter | 1200mm |

| Rewinding width | 500mm |

| Rewinding roll diameter | 400mm |

| Winding mandrel | 1"/1.5"/2" options |

| Running speed | 100-120m/minute |

| Power | 4kw |

| Power voltage | 380v |

| Machine weight | Approx. 1000kgs |

| Machine size | 2900(L ) x 1500(W ) x 1400 mm(H) |

ZHECHUANG always be your best business

Offer bag making machines with the best quality and solutions.

1. Designing upon customer's project requirements.

2. Complete solutions from A to Z depending on your bag making machine.

3. Drawing of machines and layout.

4. Machine proceeds to manufacture.

Professional and dedicated after-sales service.

1. Pre-shipment testing

2. Delivery to customer factory.

3. Phone services for the consumers' requirements on assembling products;

4. The video instructing the consumers on how to get the heaters to work or other problems.